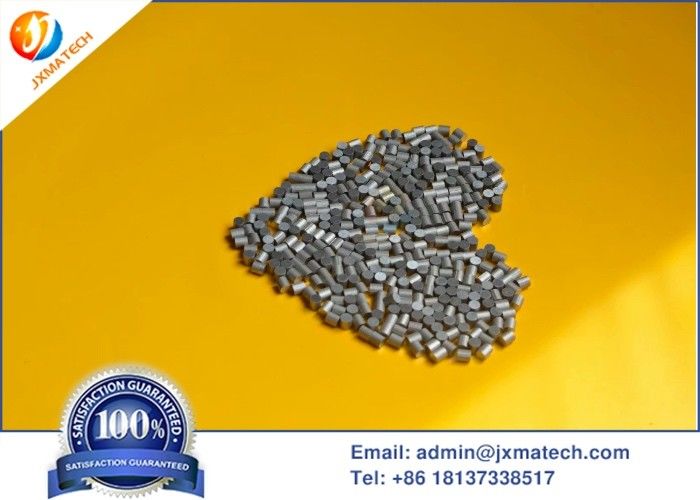

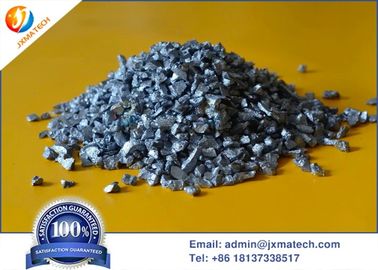

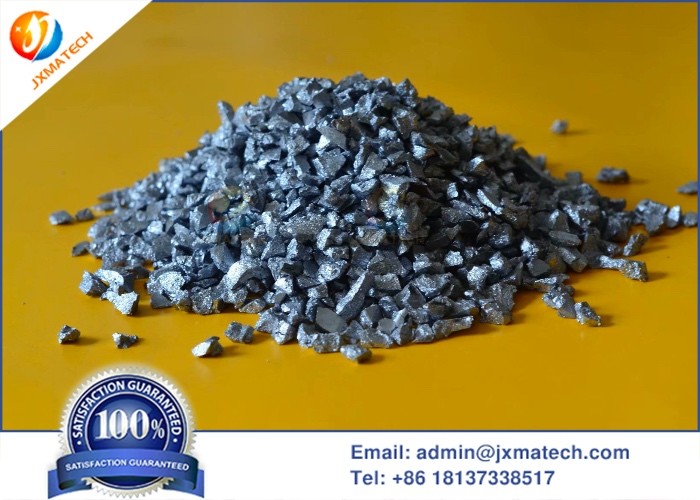

Chromium Cylinder for Evaporation 99.5%, 99.9%, 99.95%

Principle of evaporation coating:

the physical process of evaporation coating from material evaporation transportation to deposition is as follows:

1. Convert all kinds of energy into heat energy, heat the plating material to evaporate or sublime, and become gas particles (atoms, molecules or atomic groups) with certain energy (0.1-0.3ev);

2. Leaving the surface of the plating material, the gaseous particles with considerable velocity are transported to the surface of the substrate in a basically collision free linear flight;

3. The solid phase films are formed by the condensation of gaseous particles on the surface of the substrate;

4. The atoms that make up the film are rearranged or chemically bonded.

There are many kinds of evaporation coating materials. At present, there are hundreds of them are mainly used in the market. The production process mainly includes: Crystal crushing, melting crushing, wire drawing, wire cutting, granulation, pulverizing, tablet pressing, casting, molding, etc. The product shape mainly includes: wire rod, powder, irregular particle, small cylinder, small ball, cone

Chromium Cylinder, Chromium Granular are available in varying sizes

.

Evaporation coating materials: there are many kinds of evaporation coating materials. At present, there are hundreds of them are mainly used in the market. The production process mainly includes: Crystal crushing, melting crushing, wire drawing, wire cutting, granulation, pulverizing, tablet pressing, casting, molding, etc. The product shape mainly includes wire rod, powder, irregular particle, small cylinder,

Applications: optics, electronics, optoelectronics, decoration, solar energy... The coating material supplied by Jinxing company has the advantages of high purity, good density and no flash point

| Grades: |

Chrome Sputtering target |

| |

Purity: 99.5%, 99.9%, 99.95% |

| Size |

3x3mm, 6x6mm |

| Density: |

7.19g/cm3 |

| Shape: |

sheets, granular |

The main products are :

as follows: (particles, blocks and powders can be customized) aluminum particles 99.99% 3 * 3mm; 99.999% 3 * 3mm copper particles 99.99% 3 * 3mm; 99.999% 3 * 3mm iron particles 99.9% 2 * 3mm titanium particles 99.999% 6 * 6mm vanadium particles 99.9% 3 * 3mm nickel particles 99.999% 6 * 6mm chromium particles 99.95% 3-5mm cobalt particles 99.95% 2-8mm manganese particles 99.8% 1-10 mm barium particles 99.6% 2-6cm (as deoxidizer) Calcium particles 99.5% 1-3mm (used as deoxidizer) tungsten particles 99.95% 6 * 6mm niobium particles 99.95% 6 * 6mm molybdenum particles 99.95% 6 * 6mm tantalum particles 99.95% 6 * 6mm zirconium particles 99.5% 1.6 * 5mm; 99.95% 2.4 * 5mm crystal hafnium rods 99.9% d21mm hafnium particles 99.9%.

High purity aluminum Al, high purity copper Cu, high purity titanium Ti, high purity silicon Si, high purity gold Au, high purity silver AG, high purity indium in, high purity magnesium mg, high purity zinc Zn, high purity platinum Pt, high purity germanium Ge, high purity nickel Ni, High purity tantalum TA, gold germanium alloy Auge, gold nickel alloy auni, nickel chromium alloy NiCr, titanium aluminum alloy TiAl, copper indium gallium alloy cuinga, copper indium gallium selenium alloy CuInGaSe, zinc aluminum alloy ZnAl, aluminum silicon alloy AlSi and other metal coating materials.

Nucleation and growth theory of thin film materials

1. The spontaneous nucleation nucleation process is driven by the phase transition free energy.

2. Non spontaneous nucleation - in addition to the driving force of phase transition free energy, there are other factors to help the formation of new phase cores.

3. Crystal band model of film growth

There are three processes of atom deposition: vapor atom deposition or adsorption, surface diffusion and bulk diffusion.

The formation of the film structure is closely related to the substrate temperature TS / TM and the energy of the deposited atoms. TS is the substrate temperature and TM is the melting point of the deposited material.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!