Product Description

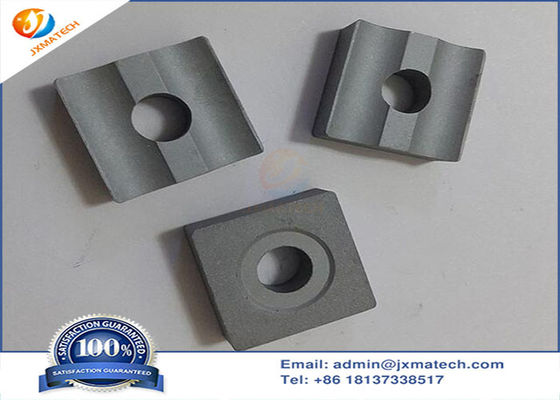

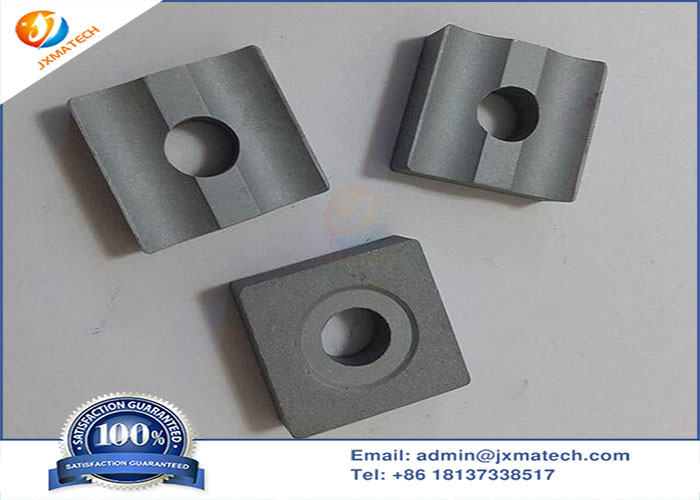

Tungsten carbide flat bars, carbide plates, carbide square bar

The characteristics of cemented carbide

Cemented carbide is made of refractory metal hard compound and metal binder phase through powder metallurgy. The commonly used hard compound is carbide. As the cemented carbide for cutting tools, commonly used WC, TiC, TaC, NbC, etc., the binder is Co, and the strength of cemented carbide mainly depends on the content of Co.

Because the carbides in cemented carbide are characterized by high melting point (for example, the melting point of TiC is 3140℃), high hardness (for example, the hardness of TiC is 3200HV), good chemical stability, and good thermal stability, and they all contain a large amount of High temperature resistant carbide, so its hardness, wear resistance, and chemical stability are much higher than high-speed steel.

The hard phase of cemented carbide commonly used in factories is mainly WC, which has good wear resistance. Although some carbides have the same hardness as WC, they do not have the same wear resistance. WC has a higher yield strength (6000MPa), so the ability to resist plastic deformation is stronger. The thermal conductivity of WC is also good, and the thermal conductivity is an important performance index of the mold. WC has a lower coefficient of thermal expansion, about 1/3 of that of steel; its elastic modulus is 3 times that of steel, and its compressive strength is also higher than that of steel. In addition, WC has good corrosion resistance and oxidation resistance at room temperature, good electrical resistance, and high bending strength. These excellent properties of WC endow it as an important component of cemented carbide.

Application of Cemented Carbide in Tool and Die Production

(1) In the field of cutting tools

Cemented carbide still maintains excellent cutting performance at a high temperature of 800-1000°C. It is suitable for fast cutting at high temperatures and has practical significance for improving economic efficiency. Therefore, it is gradually replacing high-speed steel tools. In 2017, it has not only been widely used in turning tools, planers, boring cutters, three-sided cutting tools, mold milling cutters, end mills, etc., but also with the continuous promotion of intelligent manufacturing and Industry 4.0, the application prospects of cemented carbide tools are broader , Looking forward to the future, the tool material is undoubtedly the world of cemented carbide.

(2) In the field of mould

The drawing dies and drawing dies for all kinds of steel wires are basically cemented carbide. The progressive die for manufacturing zipper teeth is made of YG8 and YG15 cemented carbide to make large-diameter drawing dies, and YG20C cemented carbide is made of multi-station progressive. mold. Non-magnetic molds are generally made of YG15 and YG20 cemented carbide, and the service life of the wire drawing dies of YG8 treated by nitrogen ion implantation is more than doubled. In short, the application of cemented carbide in molds is becoming more and more common.

Specification

| item |

Carbide heads for cutting |

| Brand Name |

JX |

| Place of origin |

Henan,China |

| Product name |

Tungsten carbide rods |

| Size |

list below, or customize |

| Application |

drill bits, end-mills |

| Material |

tungsten carbide |

| Grade |

YG6X/YG10X/YL102/YG6/YG8/YG15 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!