Tungsten Nickel Copper Alloy Bar Tungsten Heavy Alloy Rod

Our tungsten-based high-density alloy Tungsten Nickel Copper Alloy Bar Tungsten Heavy Alloy Rod is an alloy with tungsten as the matrix (90-95% W content), with elements such as Ni and Cu added, and the density is as high as 16.8-18.8 g/cm3. 2. The tungsten-nickel-iron high specific gravity alloy is an alloy composed of tungsten as the matrix (90-97% W content) and elements such as Ni, Fe, etc., and its density is as high as 16.8-18.8 g/cm3. WNiCu alloy is produced through liquid-phase sintering and alloying with added elements. Due to the different characteristics and uses of the alloy, the main components can be divided into W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu, W-Ag and other series.

The tensile strength of Tungsten Nickel Copper Alloy Bar is between 750 ~ 1100MPa. It has a super ability to absorb light. Its ability to absorb light is 30% to 40% higher than that of lead. The thermal conductivity of W-Ni-Cu alloy is 5 times that of steel molds. Tungsten nickel copper is a non-magnetic metal. Due to the toxicity of lead, tungsten nickel copper alloy has excellent environmental performance, so tungsten alloy is a good substitute for lead in many aspects.

Tungsten Nickel Copper Alloy Bar Features:

High melting point

High density (17-18.75 g/cm3)

High tensile strength (700-1000Mpa), good elongation

Good corrosion and oxidation resistance

Good thermal and electrical conductivity

Good plasticity and workability

Good workability and solderability

Low vapor pressure, good thermal stability, small thermal expansion coefficient

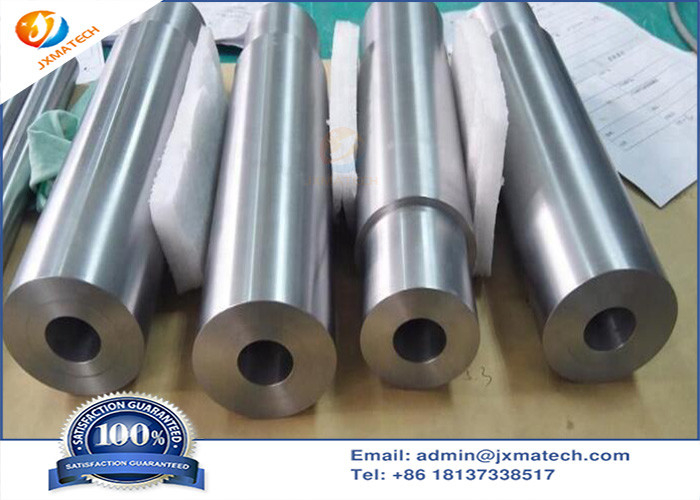

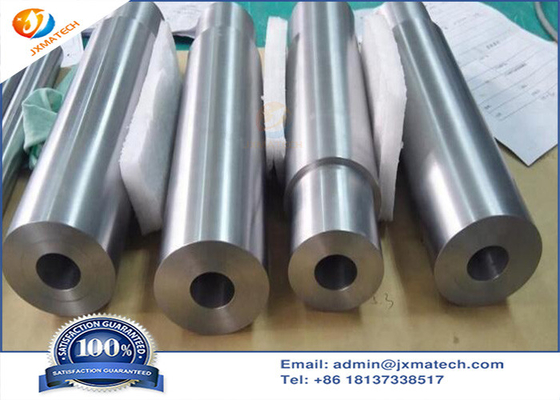

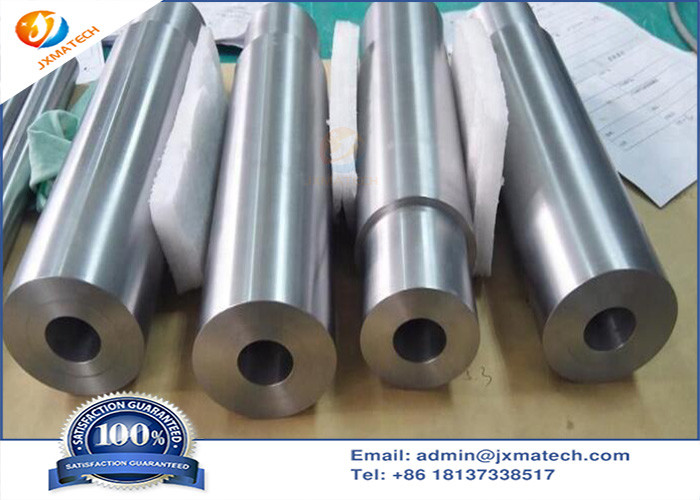

Tungsten Nickel Copper Alloy Picture:

| Composition |

90%W |

93%W |

95%W |

97%W |

|

|

|

|

|

|

| State |

Sinter |

Vacuum |

Forge |

Sinter |

Vacuum |

Forge |

Sinter |

Vacuum |

Sinter |

Vacuum |

| Density(g/cc) |

16.85-17.25 |

17.15-17.85 |

17.75-18.35 |

18.25-18.85 |

|

|

|

|

|

|

| Hardness(HRC) |

32Max |

30Max |

40Min |

33Max |

31Max |

40Min |

34Max |

32Max |

35Max |

33Max |

| Tensile Strength (Max) |

770Min |

900Min |

1400Max |

770Min |

910Min |

1440Max |

735Min |

920Min |

700Min |

850Min |

| Yield Strength(Mpa) |

620Min |

620Min |

1280Max |

650Min |

650Min |

1340Max |

650Min |

650Min |

- |

- |

| Elongation(%) |

5Min |

15Min |

5Min |

5Min |

12Min |

3Min |

3Min |

12Min |

2Min |

6Min |

Tungsten Nickel Copper Alloy Bar application

X-ray and gamma-ray radiation shielding

Aerospace, military, oil drilling and other fields;

Weight and counterweight balance

Boring bars and grinding

Electric heating upsetting anvil, piercing shell core, crankshaft balance

Rotating inertial member

Ordnance Components

High temperature tools

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!