Product Description

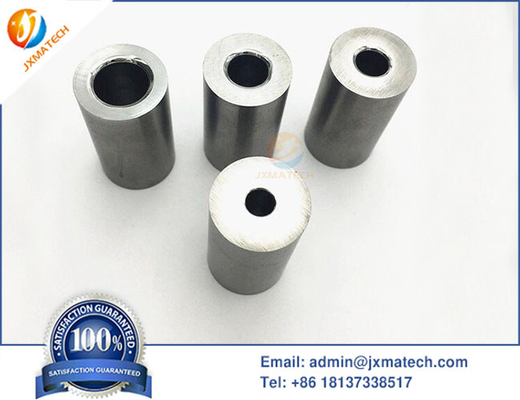

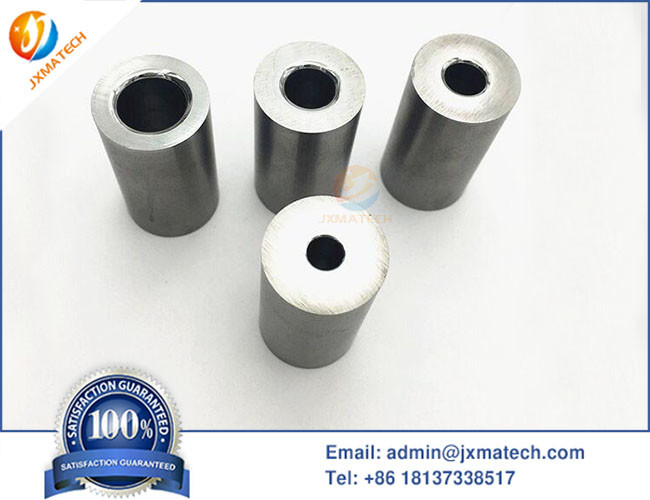

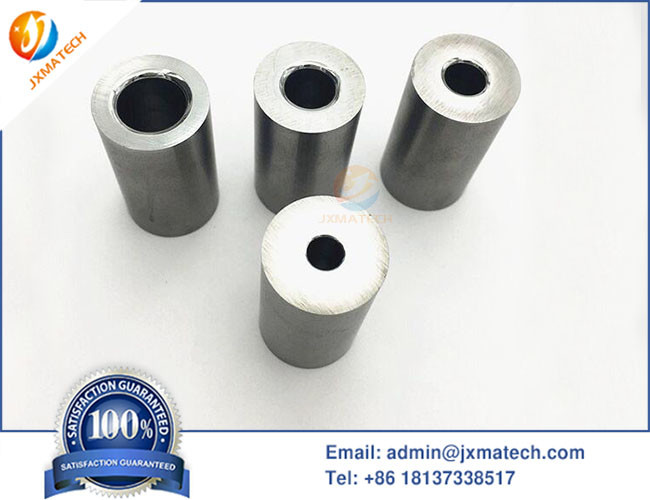

K20 Cemented Tungsten Carbide Molds With Good Wearing Resistance And Hardness

Tungsten carbide mold are made of tungsten carbide, which is a hard compound of refractory metal and bonding metal. It is made of alloy material by powder metallurgy process. Tungsten carbide has the characteristics of high hardness, good wear resistance, high strength and good toughness. At the same time, tungsten carbide has a series of excellent properties such as heat resistance and corrosion resistance, especially its excellent hardness and wear resistance. It is basically unchanged at 500℃, and still has high hardness at 1000℃.

Grades of tungsten carbide molds

| Grade |

Int'l Grade |

Density |

Hardness |

Bending strength |

Applications |

| YG8 |

K30 |

14.8 |

89.5 |

≥3500 |

It is applicable to high strength, impact resistance and earthquake resistance. It is suitable for making forming knives and wear-resistant parts. |

| YG11 |

K40 |

14.4 |

88.5 |

≥3650 |

It is suitable for making stamping abrasives. |

| YG15 |

K40 |

14 |

87.5 |

≥3800 |

It is suitable for making stamping die (processing silicon steel sheet), wear-resistant and consumable parts, etc. |

| YG20 |

/ |

13.5 |

85.5 |

≥4200 |

It has high strength. It is suitable for making stamping dies such as progressive die. |

| YG6X |

K10 |

14.9 |

91.5 |

≥3200 |

It is a fine-grained alloy with good wear resistance. It is suitable for making forming knives and wear-resistant parts. |

| YL10.2 |

K10 |

14.5 |

92 |

≥3850 |

It is an ultra-fine particle alloy with high wear resistance, bending strength, adhesion resistance and pad strength. Suitable for low speed rough machining. |

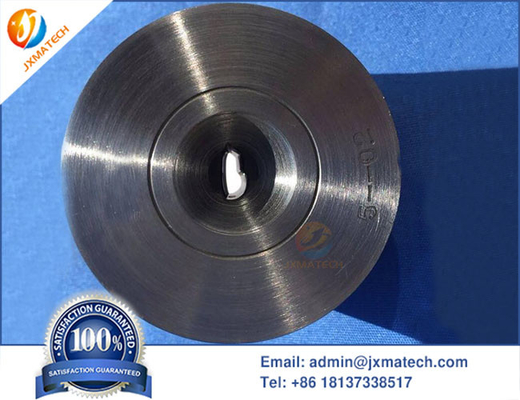

tungsten carbide molds Picture:

Product feature of tungsten carbide molds:

1, the use of cold pressing, vacuum sintering process to produce cemented carbide non-standard special-shaped alloy, stable performance, reliable quality.

2, the unique production control and detection technology, control the internal stress of abnormal products, effectively avoid products in the wire cutting crack phenomenon, away from pores, cracks and other defects.

3. Non-destructive ultrasonic testing, no sand hole, no porosity, high material density; High strength, impact resistance, high wear resistance, long service life

4, cemented carbide non-standard special-shaped products classification: cemented carbide non-standard special-shaped blade, cemented carbide non-standard special-shaped mold, cemented carbide non-standard special-shaped wear-resisting parts, etc.

5, size and specification: according to the sample or drawings provided by customers.

Applications of tungsten carbide molds:

All kinds of metal and non-metal powder pressing and stamping, high compression ratio of steel and steel pipe stretching, upsetting, perforation and high stress working stamping die, machine parts, die core, manufacturing stamping die, such as stamping watch parts, Musical Instruments spring sheet, etc.;

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!