Contact Person : ZHANG

Phone Number : 86-18137338517

WhatsApp : +8618137338517

August 30, 2022

1. Kind

According to the main chemical composition, it can be divided into tungsten carbide-based cemented carbide and carbon (nitride) titanium (TiCN)-based cemented carbide. Tungsten carbide-based cemented carbides include tungsten-cobalt (YG), tungsten-cobalt-titanium (YT), and rare carbides (YW), which have their own advantages and disadvantages. The main components are tungsten carbide (WC) and titanium carbide. (TiC), tantalum carbide (TaC), niobium carbide (NbC), etc. The commonly used metal bonding phase is Co. Carbon (nitride) titanium-based cemented carbide is a cemented carbide with TiC as the main component (some have added other carbides or nitrides). The commonly used metal bonding phases are Mo and Ni.

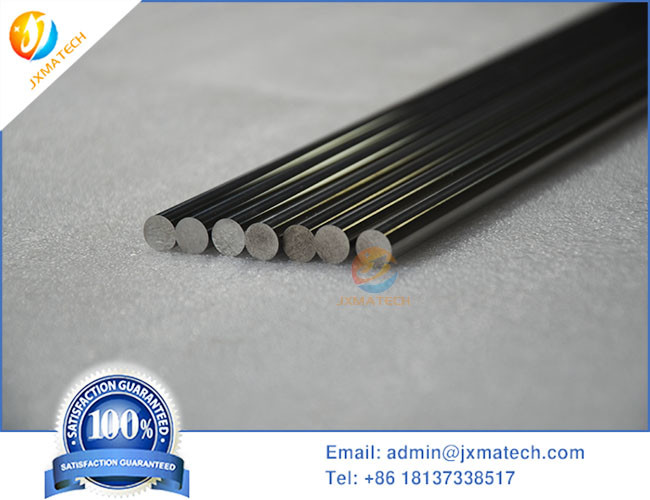

2. Features

Cemented carbide products are mainly made of carbide with high hardness and melting point (called hard phase) and metal binder (called bonding phase) by powder metallurgy method, and its hardness is very high. And its hardness value (usually 89-93HRA) will change with the nature, quantity, particle size and content of the metal bonding phase of the carbide, and generally decreases with the increase of the content of the bonding metal phase. In addition, the flexural strength and toughness of cemented carbide are also high (usually 900-1500MPa). Unlike hardness, the higher the metal binder phase content, the higher the flexural strength.

3. Application

Carbide products are often used as cutting tools for machining cast iron, non-ferrous metals and non-metallic materials, and are suitable for machining some special hard cast iron, steel, heat-resistant alloys, titanium alloys and wear-resistant insulating materials.

![]()

![]()

Enter Your Message