Contact Person : ZHANG

Phone Number : 86-18137338517

WhatsApp : +8618137338517

August 9, 2022

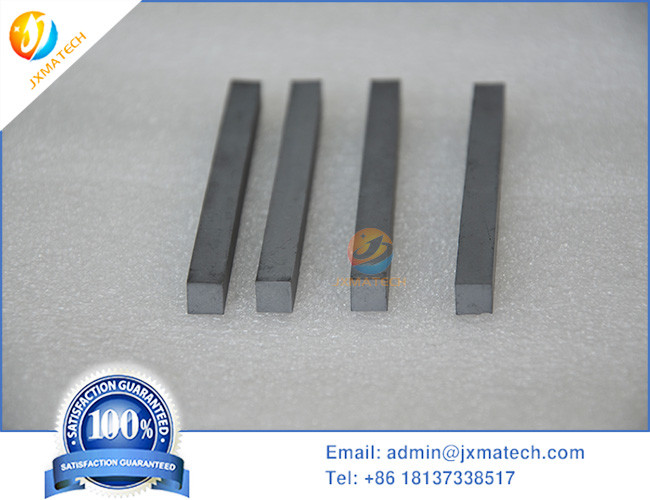

Cemented carbide is often used as a mold material and wear-resistant parts in the field of machinery manufacturing, and its main processing method is wire electric discharge. Although the wire cutting process has high processing efficiency and high dimensional accuracy, the influence on the microstructure area of the alloy surface layer is often ignored, which in turn affects the performance of the cemented carbide itself.

Cemented carbide is a hard and brittle material that is easily subjected to thermal stress with strong impact properties during WEDM. Once the thermal stress exceeds the strength limit, it will damage the cemented carbide workpiece and cause cracks on its surface. So in order to solve this problem, we can start from the three aspects of pulse width, processing current intensity and cutting times.The wider the pulse width and the greater the current, the deeper the crack. We can control the current below 2A, use high-peak narrow pulse electrical parameters and increase the number of wire cutting, make full use of the superposition effect of the temperature field, reduce the magnitude of thermal stress and its impact properties, and make the workpiece material thrown in the gas phase to avoid The surface of the workpiece is overheated and microcracks occur.

![]()

Enter Your Message